design and development of a miniaturized tensile testing machine|tensile testing machine design : service In this study, a small and handy tensile testing machine was designed to help students conduct tensile tests in class using a miniature tensile specimen. The tensile testing machine . WEB1 de dez. de 2023 · About this app. PlayPlus is content to be enjoyed wherever, however and whenever you want! Here you can rent the best films, to watch whenever you want, .

{plog:ftitle_list}

Resultado da 12 de fev. de 2024 · 41K subscribers in the deusasbrazil community. Comunidade destinada a apreciar e comentar sobre a mulher brasileira .

In this study, a small and handy tensile testing machine was designed to help students conduct tensile tests in class using a miniature tensile specimen.In this study, a small and handy tensile testing machine was designed to help .© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .

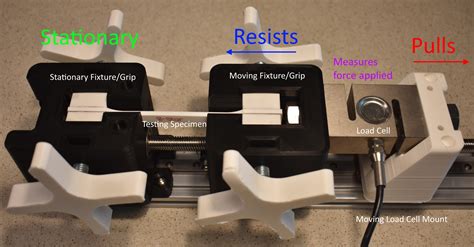

In this study, a small and handy tensile testing machine was designed to help students conduct tensile tests in class using a miniature tensile specimen. The tensile testing machine . Using a variety of test methodologies, universal testing machines are used to monitor and analyse how raw materials and component behaviour respond to tensile or compressive stresses in order to determine the physical and mechanical characteristics of these materials. increase. A tensile test specimen usually has a ‘dog-bone’ shape and one of the first standards for tensile testing of metallic materials, BS18, was published by the British Engineering Standard Association in 1904 [2].In recent years, there is a trend to miniaturize tensile specimen dimensions often referred to as Miniaturized Tensile Test (MTT) technology. Standard specimens were tested on a Zwick Z050 tensile testing machine for comparison in the subsequent optimization. In all tensile tests the nominal strain rate of the parallel section was 6.7 × 10 −4 s −1. Three samples were tested for each design to evaluate the repeatability. Download: Download high-res image (91KB)

Tensile testing machine is a machine used to test specimens, by pulling the specimen until it breaks. the results of the tensile test is a phenomenon of the relationship between stress-strain that occurs during the tensile testing process. Tensile test is a method that is used to test the strength of a material / material

tensile testing machine design

The biaxial tensile testing of cruciform specimens is an effective way to create complex loading, and is a feasible experimental method for studying the subsequent yield behavior. However, relevant knowledge gaps still exist in the geometric design of miniaturized cruciform specimens which are applicable to test machines with maximum load less than 5000 N. The present .Referring to quasi static testing, and in particular uniaxial tensile testing, different works study the development of miniaturized specimens in order to assess material mechanical properties . Miniaturized Tensile Test (MTT), as an important type of Small Specimen Test Technology (SSTT), has gained increasing attentions in the nuclear industry and other fields. However, MTT faces great challenges because the test results may deviate from standard specimens due to specimen size effects and may exhibit large scatters caused by . Design and development of a miniaturized multiaxial test setup for in situ x-ray . Gobind Kumar, Nedunchezhian Srinivasan, Ravi Kumar; Design and development of a miniaturized multiaxial test setup for in . out using the miniature sample geometry in the custom-built setup and the uniaxial standard geometry in a universal testing machine .

What is a tensile test?In the field of materials science and engineering, a tensile test is a widely used method to determine the mechanical properties of a material, specifically its response to tensile forces. It involves subjecting a specimen to an ever-increasing tensile load until it reaches its breaking point. By measuring the applied force and the resulting deformation .

mini tensile testing machine

Miniaturized mechanical testing based on small sample testing technology is a powerful technique to characterize the mechanical properties of different materials, and it is being used in different application fields. However, the small size of the specimens poses several challenges because the results are highly sensitive to measurement accuracy and the . The nondestructive nature of X-ray microtomography (µCT) associated with its suitable temporal resolution, obtained with the use of high energy polychromatic radiation from electron acceleration rings, allows in situ investigations of the damage evolution process during tensile loading in composite materials. In this context, the development of adequate scientific .

The conclusion from this work is that miniaturized tensile testing can be used with confidence as a high throughput means of predicting standard mechanical properties across a range of steels.

The aim of this paper is to present the design and manufacturing process of a tensile testing machine capable of measuring the tensile strength of polymeric materials. The present study deals with the design and manufacturing of a mechanical device to perform biaxial testing in universal (uniaxial) testing machines. A review of previous definitions of similar devices is carried out and a new device is conceived and developed. The main improvement with the present device is that it allows different types of biaxial loadings .

A critical issue in biaxial tensile tests is that the central area of the cruciform specimen does not deform to a desired level when the specimen has fractured in other areas. Contrary to the central area thickness reduction approach adopted by the bulk of researchers, this study introduces a thickness-increased sandwich specimen for large strains in the central zone . A miniaturized biaxial tensile apparatus is presented. Based on a torsional loading design, the total dimensions and weight of the apparatus have been reduced, while the output force has been . In this project, a portable horizontal tensile testing system involving the use of a specially designed tensile specimen is proposed. The system developed was designed to convert the rotation motion of a ball screw .

9h hardness tempered glass screen protector test

Fabler Hamid: DESIGN MINIATURIZED TENSILE TESTING MACHINE Paper 19 Proceedings of 8th International Engineering Symposium at Bánki [PDF] (ISBN: 978-615-5460-95-1), 2016 1 DESIGN MINIATURIZED TENSILE TESTING MACHINE ENG. FABLER HAMID Master Group of Industries Gujranwala Abstract: This work deals with the experimental validation of the proposed specimens geometries which design process through Finite Element Method was presented during AIAS 2019 and published afterwards [1]. . specimen geometry compliant to ASTM E8 and ISO 6892, specifically developed to work with MaCh3D [2], an innovative miniaturized tensile testing .

This work deals with the experimental validation of the proposed specimens geometries which design process through Finite Element Method was presented during AIAS 2019 and published afterwards [1]. In particular, non-conventional miniaturized specimen geometry compliant to ASTM E8 and ISO 6892, specifically developed to work with MaCh3D . One of the few examples of design of an ad- hoc miniaturized machine is reported in the work of Lim & Kim, (2013), which deals with the design of a miniaturized tensile testing machine with similar constructional and operating aspects to .[2], an innovative miniaturized tensile testing machine, were considered. The size-reduction of specimens is advantageous both in terms of material and equipment: smaller specimens require

Instron manufactures tensile, compression, fatigue, impact, rheology, and structural testing machines, testing a variety of materials and range of applications. Telephone: +1 800 877 6674A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the tensile strength and deformation behavior until break.. A typical tensile testing machine consists of a load cell, crosshead, extensometer, specimen grips, electronics and a drive system.DOI: 10.1016/J.FUSENGDES.2020.112006 Corpus ID: 224878397; On the standards and practices for miniaturized tensile test – A review @article{Zheng2020OnTS, title={On the standards and practices for miniaturized tensile test – A review}, author={Pengfei Zheng and Ran Chen and Haiting Liu and Jiming Chen and Zhijie Zhang and Xing Liu and Yao Shen}, .development of the biaxial tensile testing technology, the design of test specimens has been greatly improved. For instance, according to the proposal made by Lebedev [6,7], a row of thorough slits . designed for testing on a high-power test machine, while the design of miniaturized specimens tested on low-power testing machines (the maximum .

9h pencil hardness test

[1] Bergonzi L, Vettori M and Pirondi A 2019 Development of a miniaturized specimen to perform uniaxial tensile tests on high performance materials Procedia Structural Integrity 24 213-24 Google Scholar [2] Bergonzi L, Vettori M, Pirondi A, Moroni F and Musiari F 2018 Numerical and experimental validation of a non-standard specimen for uniaxial tensile .

Subtitles for: The End of Love (El fin del Amor) (S01)(Demostrando lo improbable) Season 1 Episode 3 Subtitles for: The End of Love (El fin del Amor) (S01)(Una desconocida llega a la ciudad) Season 1 Episode 4 Subtitles for: The End of Love (El fin del Amor) (S01)(Exploradores del amor) Season 1 Episode 5

design and development of a miniaturized tensile testing machine|tensile testing machine design